Frequently Asked Questions

- MPS NItrous

- MPS Air Shifter

- MPS Wiring

- Data Logger

- K&P

- MSD

- NOS

- Dyna

- Dynojet

I am installing a NOS kit on my BUSA 2004. Looking to get around 70-80HP shot. I am pretty sure the OEM pump won’t do the work as it normally is good for a total of around 200-220 max. I did buy in the past your pump 1-0506 for my DRAG Warrior. I think this pump would be good as well for the BUSA.

Questions: 1)

If i get your 1-0506 to replace the OEM pump, do i need to remove the OEM from the tank and install your cover 63-111? 2) In NOS kit there is always a fuel pump 3-15760, do I need to still use it? 3) I will need bigger injectors, what do you recommend? If it was mine I would use P/N 1-0510 Spyder Dry Kit, P/N 1-0449 62lb injector kit, P/N 1-0622 in tank fuel pump, P/N 1-0494 ECU reprogramming for the 62# injectors, P/N 35-20-023 power commander V, P/N 1-0500-V Map Switch Relay, P/N 3-15974 NOS Mini Progressive controller or if you take a laptop to the track P/N 64-NC-2, Daytona Progressive Controller, and a P/N 2-4227 MSD SB-6 Ignition control. We like a dry kit over the wet kit because we have more control over fuel delivery. You will need more fuel than your stock injectors and pump can provide so you will need the fuel system upgrades. The progressive controller and the map switch will automatically control your nitrous power seamlessly. Anything over 40 HP on pump gas or 60 HP on C-16 will need to have an ignition retard. This is the case wet or dry. Hope this helps.

I have a customer that has a ZX-14 that I built a motor for. I installed a 40 shot of NOS and the Daytona NOS controller I picked up from you guys. As I mentioned the motor has been built up. He is wanting to run a 125 - 150 shot of NOS. Can this be safely accomplished using a dry kit? If this is common for bikes to run a heavy shot of dry nitrous, will we need bigger injectors? Or do we need to switch to a wet kit? And if we switch to a wet kit, can we use the stock injectors or will we still need bigger ones.

I guess what I am asking is, what is the best, safest way to accomplish my customers goal? We like a dry kit. We have dry on our Pro Mod Hayabusa. We have made 300 HP with stock ZX14 injectors. A good fuel system (pump & Injectors) is mandatory for dry systems. To find out what injectors you would need follow this formula: You will need to know how much total horsepower you will make. Then multiply this by .55 BSFC then multiply by .8 then divide by 4.

This will give you the minimum injector size needed to support the HP you will run. We use a power commander 5 with a MPS Map switch relay. I would recommend a progressive controller like the NOS mini to control the system.

You will need a way to retard timing also. We use the MSD SB-6. Hope this helps.

I have a 2005 Kawasaki ZX-10R and basically my question is how safe is this for your engine... seeing as your obviously injecting a lot of explosive content into an aluminum engine block... and when injected does it just squirt nitrous or is it a nitrous/fuel mixture entering the engine.... I just don't want to install this kit and use it a few times and have it blow up my engine or something.... and can the average person with basic knowledge of motorcycles install this kit on a weekend or something...Thanks for your time Nitrous oxide is an oxidizer. It is not flammable. It does contain twice the oxygen molecules of air in the atmosphere. You will need to add the appropriate amount of fuel to maintain the correct air/fuel ratio when the nitrous oxide is introduced. You can do this via a power commander or a Fast IF Mixture Control. Yes, The average person can install these items in an afternoon. A trip to the dyno for correct tuning and to be sure you have the correct A/F ratio.

Is it ok to mount a 10 oz bottle on its side rather than vertical? You will lose capacity. Nitrous is liquid. With the bottle on its side it can only pick up from 1/2 way full and above. Plus you have the slosh factor. 10 OZ bottles have no siphon tube and must be mounted upside down or have a siphon tube installed.

I have a 2004 GSXR 1000 the nitrous system is installed, my question is, is it necessary to have a purge system and if so can you recommend one. Thanks No it isn't necessary. A purge is needed when you heat bottles to above the running pressure before you run. Then purge them just before they run so they know exactly what bottle pressure they have at the start of their run. Everyone else does it because they think it looks cool.

Hey, I have an 03 gsxr 1000 with a power commander, will I have to remap the bike? Also you said it won't damage the engine with proper fuel added, what is the proper fuel? You are adding oxygen with nitrous so you must add fuel. The factory inlet temp sensor being cold from the nitrous will compensate for small HP gains without modifications. As you get more HP you will need more fuel than the temp sensor can provide. You can then use a power commander or our Fast FI Mixture Control to add fuel to the mix. For really big HP you will need the Fast FI with its instant rich feature. This locks the injectors open while the nitrous solenoid is on. The best way to tune any of these combinations is on a dyno with a O2 sensor to provide you with fuel mixture information. The more HP you make the more stress is involved on all engine and drive train components.

Hello, I have an '03 Ninja 636-R, I've seen some questions where you say you will need a power commander for this bike, and others you say as long as you run the 20hp jet, you don't need a power commander, could you clear this up, Thanks a lot. The best way is to tune on a dyno. Make a pull with the 20 HP jet and check the A/F ratio. If it is OK then you are good to go. If not you will need to richen mixture with a power commander or MPS Fast FI.

I am looking at installing a nitrous setup on my 04 zx10r...I saw that you offer a MPS fast FI mixture control...will this work on my bike? Is the install pretty straight forward or very extensive??? Will it work with a Dynojet PCIII USB??? Also what advantage is it in using a M P S Dry Nitrous Dual Nozzle Kit?? I am looking at all options and will use it if it helps. When you have a higher horsepower kits the Fast FI is a necessity to deliver the most possible fuel. The install is easy. It has a power, ground, wire to each injector, and the instant rich lead that goes to your nitrous system. It will work with a Power Commander using only the instant rich feature. The dual nozzle kit just offers a little better distribution of nitrous when using a dry kit.

Any experience installing this product on a 900 air cooled ducati SS? post '99 fuel injected motor, of course. if so what is the procedure for a moderate gain target? No experience with that specific bike.

Hey i was wondering when the nitrous would shut off when you let go off the starter button or otherwise thanks. When you release the button the nitrous shuts off.

i just bought a gsx-r750, i put 1000 miles on it, im thinking about getting a yosh rs3 bolt on pipe and i was looking at this kit.. i just want a quick 20 hp gain, what are the chances that it will do damage to my engine..and what can i do to make it more efficient. 20 HP is not a problem. We recommend our MPS Fast FI Mixture Control or Power Commander to add additional fuel.

How long a shot can i get with a 1LB tank if i held it till it was empty... just to get an idea of how many shots i would get (everyone has a different idea of how long a shot is) 20 - 25 Seconds

Okay, one more question before I beg my wife for the money for this system, hahahaha. How do you regulate the horsepower boost from 20hp, to say 40hp, because you recommended a 30hp to 40 hp shot for my Gixxer 750. And if you could give my wife Gina some reassuring words about how safe your product is helps me all that much more. The kit comes with jets to regulate the amount of nitrous that is injected. It comes with a .028" jet, .032" jet, and a .036" jet. Corresponding to approx 20, 30, and 40 HP respectively.

Now with a 30 or 40hp shot in my Gsxr 750, what gear should I be in to safely hit my nos button, and what is an A/F ratio module, please help, thank you Air Fuel Ratio. I would try 3rd gear first then second.

I have a Suzuki Gsxr 750 with a yosh (EMS) engine management system and TRS yosh pipe, I also have motor upgrades and mods, the bike is a 2003 with 15755 miles on it and it runs as strong as the day I bought it, what kind of shot do you recommend that I should use I would probably use 30 or 40 HP jets. Always run it on a dyno with a A/F ratio module so you can see if you have enough fuel to support the additional nitrous.

I have a Honda Cbr 600RR. It's all stock except for an RS-5 yosh. Do I need to upgrade anything like my fuel pump etc. Also can this set up damage my motor at all. How much can I use it. No upgrades to motor if you use small jets. We recommend a dyno pull after install to be sure you aren't lean. Use it all you want.

I saw that it will work on my V-Twin TL1000S if I read correctly. What modifications will I need to make to accomodate it and how big of a deal is it to install? Easy to install. If you use the small jets you won't need anything other than a power commander or Fast FI unit.

can this system be used on a small 49cc pocket bike motor? Ive done an online search at google for a nitrous kit for these bikes and I cannot find a supplier... this is an exploding market, the bikes are reasonably priced, an inexpensive kit for pocket bikes would sell well... because there IS no kit currently available... I look forward to your reply and any thoughts concerning this No, this kit is for fuel injected bikes.

i have a 01 zx12 will it add alot i have exauhst and power comandere 40 plus HP

will it work on harley If its fuel injected.

yes how hard would this kit be to hook up to a tl 1000r and will i need anything extra is there a special application for a v-twin There is no special application for V-Twins. It would work with the TL.

I have a 03 kawasaki zx6rr ninja, do you have you have dyno charts of that? if i use super premium gasoline without the Fast FI Mixture Control Unit, will it be alright. No, we have no dyno charts for that bike. You should be able to use the small jets with a power commander set to richen the top 90% throttle opening.

Will the system be fine in the cold? It will run richer in the cold weather. You may need to increase jet size to compensate for lower bottle pressures.

I want to know if I would have to change any of the stock components like the piston to have the system installed or can I stay factory..I have a 99 gsxr750. No, you can get moderate horsepower increases without changes to pistons.

Have '02 roadstar warior, will this kit work? If it is fuel injected the kit will work.

Do you have any no2 kits for a 99 gsxr 600 carb NOS 4 cylinder kits p/n 3-03008nos will fit your application.

I have an 04 gsxr750. I want to get about 20 hp out of the system. Would it be better to get the commander, or will it be fine. how hard would it be to wire the kit to the passing light switch. You can probably get away with nothing for that small of a HP. But, you really should go to a dyno and find out the air fuel ratio before you use it extensively. If it is lean you will need a power commander or other means of richening the fuel mixture.

I have a 02 gsxr1000 and would like this system. Can I run it without adding more fuel? or will it harm my motor. How big of a shot is this system and how much can I run without more fuel. You can run the smaller jets with no added fuel. The air temp sensor will add more fuel for this type power settings. For more power our Fast FI Mixture Control or a Power Commander will be necessary.

How many nozzle does this come with. If only one, can I get an extra one? Does it work off of a full throttle switch? It comes with one nozzle. We offer a dual nozzle kit. You can wire it for a full throttle switch but it comes with a starter button switch swapper.

Do you guys offer purge soleniods for this kit? Yes, but there is really no need for them unless you just want the look of a purge.

I've got a 03 honda 954RR does your kit wire directly into the factory wiring harness. also is their any thing special ill need to do when installing this kit on this bike? You will need to cut the wire that runs from your starter button to your starter relay to install the kit. That is really the only wiring that is needed.

I have a 04 zx10r ninja what would i need to put nitrous on it. just the kit or do i need a power commander. i want to try to get 40hp out of it. what would you recommend. I would recommend our Fast FI Mixture Control Unit or a Power Commander for 40 plus HP levels.

Where would i fill the bottle? Any NOS retailer, speed shop etc.

Hey, I have an 03 gsxr 1000 with a power commander, will I have to remap the bike? Aslo you said it won't damage the engine with proper fuel added, what is the proper fuel? You are adding oxygen with nitrous so you must add fuel. The factory inlet temp sensor being cold from the nitrous will compensate for small HP gains without modifications. As you get more HP you will need more fuel than the temp sensor can provide. You can then use a power commander or our Fast FI Mixture Control to add fuel to the mix. For really big HP you will need the Fast FI with its instant rich feature. This locks the injectors open while the nitrous solenoid is on. The best way to tune any of these combinations is on a dyno with a O2 sensor to provide you with fuel mixture information. The more HP you make the more stress is involved on all engine and drivetrain components.

Can the solenoid be mounted further away from the bottle, like under the Tank on a Hayabusa. I want to hide the solenoid and wires so no one can mess with them and then run a steel braided line to the solenoid Sure. You will need 2 1/8NPT Male x #4 AN Male fittings and a length of #4 line with 2 #4 AN hose ends.

How much experience does it take to install this syste? What other products are needed in order for this system to perform at its best It would take average mechanical skills. The optimum system would use the Fast FI Mixture Control to add additional fuel.

Will it make a difference for my V-Twin TL1000R? I have heard that it will harm the injection system. But at the track I would like to have a couple mph gain in my last gears. It won't hurt injectors. You should be able to get 20-30 more HP without much problem.

I have an 02 gsxr 600 completely stock(fuel injected) is the nitrous going to damage my engine in any way? No, not in moderate amounts with the proper fuel added.

I have a Suzuki Hayabusa 1300 CC. I know the kit will work, but what are the deminsions of the bottle. I want to know the lenght and how it mounts to a bike 3" diameter x 10" long. You will need to fab your own mount of we have a billet bracket for $39.00.

u have any test on a 2001 honda 929rr......will this work for my bike.Will i be able to tell the difference? If your bike is fuel injected it will work and you will be able to feel a difference. We have no dyno charts for that bike. Sorry

are there any dyno sheets avail? I own a 2002 GSXR 750... just want to see some hard numbers. thanks Not for a 750.

does it have a TPS so that it only comes on at WOT? No, it has a switch swapper that converts the starter button into the nitrous button. The nitrous is only on when you push the button.

Hey, I have an 02 yamaha r6, would this dry kit work with my bike?? If your R6 is Fuel Injected it will work fine.

I have a 2003 gsxr 1000 and I have the mps air shifter with just the basic kill box what box should I get to set the bike up for auto shift. There are 2 ways to go. You can replace your present kill box with a 1-0299 Sport Bike Autoshift with kill. It has the same plugs and would require no wiring whatsoever. You would then have your existing kill as a spare or you can sell it (lifetime warranty still applies). Or you could add a 1-0010-720. This would require tapping into the wires of the present kill box. Either option would require MSD rpm modules. 2-8751.

When I uses the engine kill that connects to the coils my FI light comes on. Is this normal? Yes, it senses the ignition interrupt. You can cycle the key to reset the light. You can do this while going. The FI light does not trigger a limp home mode. The light is just a warning of an abnormal condition and will not have any effect on the way it runs.

What would make my kill time too long?Most times if the kill time is too long it is one of 3 things:

The adjustment pot has been broken (turns all the way around and doesn't stop).

The brown wires are on the positive leads (all the same color wires) on the coils.

The blue activation wire on the kill is being supplied a 12 vdc positive signal instead of a ground.

I have an MPS air shifter kit and i've noticed that my air shifter solenoid seems to have a slight air leak. it's usually a tiny leak until i pressurize and activate it for the first time. after that the leak gets a little worse until the system has fully depressurized. is there anything that i need to lubricate to keep this from happening or do i just need to get another solenoid? If it is leaking out the exhaust port, (this is the most common leak), you can usually adjust them to stop leaking. The small round black plastic piece on the bottom of the air valve is a stop for the cartridge (piston) that moves up and down to direct the air to the correct port. The cartridge has several small o-rings that must be aligned in the correct spot: a small amount off can result in a leak. Adjusting the stop raises and lowers the cartridge position. We use snap ring pliers to adjust the stop. You should not have to go more than 1/6 turn in either direction to stop the leak. If this doesn't stop the leak it may have dirt in the valve which can be cleaned by removing the stop and cleaning the cartridge valve. If none of these methods work it may be time to replace your air valve.

I am installing a shifter on my 2000 GSXR 1300 and was wondering if i could use NOS instead of CO2? I am going to use a paintball bottle for the gas so will one of your bottle valves and regulators work for me? You shouldn't use nitrous oxide for your air shifter because the seals in the cylinder and valves in your air shifter are made of Buna N rubber. Nitrous oxide attacks this material deteriorating it in a short time. It may work for a while but seal life will be a problem. I would recommend CO2. The paintball bottle probably uses a 5/8" - 18 thread. Most DOT Air Bottle threads are 3/4" - 16. Our regulator kits come with a 3/4" - 16, but we have the smaller 5/8" - 18 bottle valves as well. You just need to specify that you need the smaller valve. We also have filler adapters so a paintball refiller can also fill your shifter bottle.

I use an old air shifter push button with a MSD shift light and MSD MC1 with two step box. I want to know if I buy an Auto-shift control box, what part I have to change to run with this unit ? I think I have to change the air micro switch to an electric solenoid ! Do you want to confirm that ? I am assuming you have a air over air system like a MRE Junior shifter. You will need the following components to convert it to electric over air style necessary to use the Autoshift Control Box. A Pro Button w/air ports p/n 1-0186 & Electric Air Valve p/n 1-0037. The Autoshift p/n 1-0010 will work correctly with your ignition and the above component

Do you have a diagram for a 24v start system? No, but you just take the wire that feeds your starter now and connect to the 2nd battery's negative terminal. Connect the positive terminal to the starter. This will give you 24 volts to start the bike. You will have to charge the 2nd battery separately or use the Tiger Racing harness.

When I uses the engine kill that connects to the coils my FI light comes on. Is this normal? Yes, it senses the ignition interrupt. You can cycle the key to reset the light. You can do this while going. The FI light does not trigger a limp home mode. The light is just a warning of an abnormal condition and will not have any effect on the way it runs.

I recently purchased a MPS Electronic Engine Kill for my 2000 Suzuki GSXR 1300. I am having a difficult time determining the colors of the negative wires on my coils. Can you please help me with this problem? You probably have 8 wires going to your 4 coils. 4 should be of a common color. (gray for the Hayabusa) The common colored wires are normally the positive side of the coils. You will hook up the 4 brown wires to the negative side of each coil.

I recently installed a MPS electronic engine kill on a 2000 Suzuki GSXR 600. My 4 coils are a parallel connection. There are 2 coils in pairs, which makes it very hard to determine where the 4 brown wires connect to? Do I connect all of the 4 wires or just 2 wires?? When wired in parallel You should have two wires coming from your ECM, one going to cylinder 1 or 4 with a jumper wire between them and the other to cylinder 2 or 3 .with a jumper wire between them. Then you should have power going to the remaining four leads. If this is the case you would connect two brown wires to the two leads coming from the ECM. Then ground the other 2 brown wires.

Can you help with some instructions for hooking up your air clutch.....most importantly the red / blue / green / wires coming from the switch under the clutch handle? I know these are for a two step but where do these wires hook to? These wire connections are the same for all MPS clutch lever switches. In electrical terminology the red is the switches common pole, blue is normally closed, and green is normally open. In easier to understand terms the red and blue are connected when the lever is out while the red and green are connected when the lever is pulled in. In most cases the blue wire is not used and the two step device is connected to the red and green wires. It depends on the model of two stage rev limiter where you hook up the wires. You will need to consult the directions of the specific product you are using.

Will the Daytona WEGO II Wide Band O2 system work on a 1996 zx-750-p it is not fuel injected. If yes, about how much horse power will I gain? Are there instalation instructions included? The Daytona WEGO II Wide Band O2 System will work on any 4 cycle gasoline engine and comes with complete installation instructions. It is a data acquisition system, therefore you will gain zero horsepower by just installing the WEGO II. However, you will gain vital information for tuning your bike. A good tuner can use the WEGO II to make more horsepower while preventing costly engine damage.

I am considering a Data Logger purchase. I own a turbo pro-mod bike. The 60-DL10KIT seems to have a good basic function. I would want to monitor engine RPM, wheel speed and boost pressure. What would I buy to have this unit do what I need? Is there modifications required during install, it seems to be primarily directed towards car use. The RPM Performance data logger comes with all functions you need with the exception of a 0-50 pressure sensor and analog cable for the boost measurement. It comes with a magnet collar that may need to be machined to fit your countershaft sprocket. I had to machine both the sprocket and the collar for my bike. You will also need to fabricate a mount for the sensor to pick up the magnet collar. The system was designed for automotive use but is perfectly suited for motorcycle use. I researched quite a few data acquisition systems before deciding to carry this one. Tech support is something to consider as well when buying a system.

A word from K&P Engineering, manufacturer of the world's finest oil filters: "Thank you for your interest in our filters. We think it's great that people are calling attention to the importance of oil and it's filtration. The more information we can get to people like you the more our product will stand above the competition. Remember, oil is the lifeblood of your machine..... keep it clean!"

Where is the K&P Engineering filter made?

Proudly designed, engineered, sourced and manufactured in the USA. Make sure you receive a genuine K&P Engineering product.

Has this type of filtration technology been proven?

This type of filtration has been in use for many many years and has proven itself in NASCAR, Formula One, the Military and in the Aerospace industry. We have been inventing, designing engineering and manufacturing oil filters using this proven technology since 1995. K&P Engineering also manufactures oil filters that are FAA approved for certified aircraft.

What kind of materials are used in the K&P Engineering oil filters?

The filter housing and filter element end caps are carved out of a solid chunk of 6061T6 billet aluminum, which not only looks great but aids in dissipating heat and reducing weight. The filter element is made from medical grade, type 304 stainless steel micronic filter cloth to provide unmatched protection against oil contamination and resultant engine damage. A super strength neodymium rare earth magnet is installed in the top of the filter element used in the spin on models, which provides magnetic pre-filtering of the oil. The adhesive used in the filter assembly process is good to 600 degrees Fahrenheit, far above normal operating temperature of 180 to 300 degrees. The hydraulic quad-ring gasket doubles the seal between the filter housing and the engine and helps provide burst pressures exceeding 1000 psi.

How does this type of filtration compare to paper oil filters?

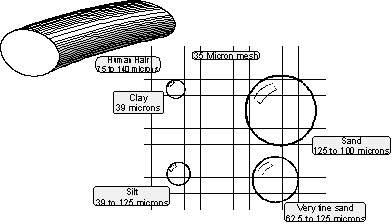

We use ASTMF316 testing procedures which eliminate many of the user variables found in the SAE procedures. Basically, the filter media is pressurized from one side, and when the media starts passing particles, that is the micron rating. We sent filter media from several common brands of paper filters to the lab to be run through the ASTM test. We sent the media to the lab with no names, just numbers for identification so they wouldn't have any idea what brand filter they were testing. The results for the paper filters ranged from 48 microns for the best filter to over 300 microns for the worst filter. Our tests were right in line with other testing results we have researched that have paper media filters passing particles anywhere between 50 and 90 microns. What does this mean? Paper filters are rated on averages, percentages of efficiency (also known as beta ratios) and multiple passes, so a 10 micron rated paper filter (as advertised on the packaging) may be letting particles 50 microns and larger through. The medical grade stainless steel cloth that we use is consistent across the entire media surface and is rated at 35 microns, meaning nothing larger than 35 microns should pass through the material. The bottom line is we meet or exceed the filtration performance of OEM filters, eliminating any warranty issues.

What Are Microns?

A micron is one thousandth of a millimeter. That's approx. .00003937 inches.

35 microns is about .00138", (just over one-thousandth of an inch).

The lower limit of visibity to the human eye is about 40 microns.

Pollens range from about 30 to 50 microns

A white blood cell is about 25 microns

Cigarette smoke is about 10 microns.

What about flow rate and why is it so important?

A very important dimension of oil filters is the flow rate. It doesn't matter how good the filter media is if the oil is going through the bypass due to a low flow rate. We believe many people mistakenly chase smaller and smaller micron ratings to try to get cleaner oil. Flow rate is decreased exponentially as the micron rating is decreased. Again, once the flow is restricted to the point the bypass opens, the filter media rating becomes a moot point. This is why we meet or exceed the filtration of the factory filters to meet warranty requirements, while concentrating on providing maximum flow. This combination delivers the maximum combined benefit from the oil filter. A one-inch square of our filter material can flow 1.9 gallons of oil per minute at only 1-PSI pump pressure (70 degrees F). This means the stainless steel filter cloth we use in our small spin on filter element can flow 57 gals/minute.

We have run static pressure tests between our filters and paper filters for an identical application. For the same sized filters, our stainless steel micronic filter consistently flowed over 7 times more oil for the same time period than did the paper filter (tests were run at 68 degree ambient temperature). How does this affect what is going on inside your engine? We installed pressure gauges on each side of the filter element on a pro stock drag race engine so we could measure differential pressures (the difference in pressure between the input side of the filter element and the output side of the element). During a full pass down the strip the differential pressure of the stock paper filter measured 20psi difference. Our filter measured less than 1psi difference. Less differential pressure means less chance of bypass operation, faster oil pressure at startup, less drag on the oil pump (potential horsepower gains) and higher flow through the engine, often helping to cool the oil and keep the crankcase cleaner.

Another thing that can affect the paper filter flow is moisture. Not everyone is aware that engines get condensation in them. When paper gets wet it swells and may pass even less oil.

Now, think about all the particulates that have had a chance to settle to the bottom of the oil pan right where the oil pickup is... just waiting to go through the bypass valve directly to the engine components...

Will this filter affect the performance of my engine?

The reduction of backpressure against the oil pump will result in varying amounts of horsepower gain. It depends on your specific engine combination and application. We have seen as much as 5 hp gain, to very little or no gain depending on the drag the oil pump is producing in a specific circumstance. It is definitely not going to reduce performance. The higher oil flow through the engine along with the heat dissipation provided by the finned aluminum housing usually results in cooler oil temperatures which can help with performance as well and engine life.

Why do you promote inspecting the filter contents?

Mechanics have been cutting oil filters apart for ages. It's one more way to "read" what is happening in the engine. Our filter makes it much easier than cutting apart messy paper filters. By checking the particles that get caught in the filter you can identify abnormal wear and prevent catastrophic engine failure. It's a lot less aggravating to replace a rod bearing that's starting to go, than to be standing next to your machine staring at that same rod sticking out the side of the engine!

What is K&P Engineering doing to help protect the environment?

With the cleanable, reusable design you no longer will be sending oily paper filters to the landfills (some states don't even allow oil filters to go to the landfills...they must go to through special, expensive disposal processes). What does come out of the reusable filter during cleaning can be sent to the recycling center with the rest of your old oil. All of this helps prevent water and soil contamination. In addition, the environmental impacts of creating new paper filters is reduced, from steel production, media production, glue and painting. This oil filter truly is a renewable resource.

I have a high oil pressure application and need a high burst pressure similar to specialized paper racing filters. How much pressure will the K&P Engineering filter take?

Our spin on filters have been pressure tested to over 1000 psi. Let us know if you need more than that.

Why don't you have an Anti Drain back Valve?

Many filters have a rubber flap over the intake holes that is an attempt to keep oil in the filter and minimize the time it takes to fill the filter when you start the engine (they call it an anti-drain back valve). A test you can perform to see how well this "valve" works is to fill a filter with oil, plug the large center spin on hole with a bolt, lay it on it's side and then see how long it takes for the oil to drain past the rubber flap. We have found (and have read other published tests) that the filter eventually ends up with the same amount of oil in it as if it didn't have the flap, it just takes longer to drain out. If the flap worked as planned it would be beneficial to have the extra oil in the filter at startup. On the other hand, that flap covering the intake holes is one more restriction the oil has to get by to get through the filter and back to the motor....

How much oil does this filter hold?

Slightly more or less than the stock filter depending on the specific application. It doesn't really make any difference because of our filtration and flow capabilities. Continue to use your manufacturer's prescribed method of checking to make sure there is the proper amount of oil in the engine (usually via a dipstick).

How do I install and remove the K&P Engineering filter?

A cup wrench is included with almost all of our spin on filters that mates to the 14 flats machined into the bottom rib of the housing. Please reference the instructions section on this website for detailed instructions.

What if I accidentally ruin the filter element (I stepped on mine...)?

Not to worry...individual replacement parts are available through your dealer.

How do I clean the filter?

Please reference the Cleaning instructions tab on this web site.

Tell me about the filter sealing gasket (Quad Ring).

Our housings are designed and specially machined to utilize a quad ring as the sealing mechanism between the housing and the mounting surface. Quad rings are commonly found in hydraulic applications and have a high reusability factor. Along with our engineered housings, we have achieved burst pressures that exceed 1000 psi. You normally will be able to use the same quad ring for several oil changes. If needed, you can flip the quad ring over and use the other side for an additional oil change. A single quad ring can last for several years. New filter kits have a spare included in the packaging. Quad rings are more sensitive to dirt than the old square gaskets so make sure the mounting surface and quad ring are both free of debris before installing the filter. If you have had a quad ring tear, make sure you don't have any burrs on the mounting surface, and be sure to lube the quad ring well with oil before installing the filter onto the engine or remote mount. Replacement quad rings should be available through the majority of our dealers, or can be found at hydraulic supply shops. The part numbers are as follows:

| K&P Part No | Industry Standard Part No | Fits these housings | Used on these filter part numbers |

| QR1 | QR -141 B70 | C1 | S1, 2, 9 |

| QR2 | QR -230 B70 | C2, C3, C4, C5 | S4, 5, 10, 15-19, 25, & aircraft |

| QR3 | QR -337 B70 | Gasket plate | S19 |

If you have difficulty locating a replacement, send your contact information (including mailing address) and part number needed to info@mpsracing.com and we will have someone contact you.

Will this filter affect my warranty?

No. Under the Magnuson-Moss Warranty Act, 15 U.S.C. SS 2301-2312 (1982), and the general principles of the Federal Trade Commission Act, a manufacturer may not require the use of any brand of filter unless the manufacturer provides that item free of charge under terms of the warranty. So, if you are told by a dealer that anything other than a specific brand of filter will void your warranty, ask for the statement in writing (you won't get one), and request that filter be supplied free of charge. If you are charged for the filter, the dealer will be violating the Magnuson-Moss Warranty Act and other applicable law. This is a federal law and the Federal Trade Commission has authority to enforce it, including obtaining injunctions and orders containing affirmative relief. For more info do an Internet search on "Magnuson-Moss Warranty Act".

Here is a link to one of the Federal Trade Commission's guides for those offering warranties. Look for "Tie-in Sales provisions". http://www.ftc.gov/bcp/conline/pubs/buspubs/warranty.shtm Here is the text:

"Tie-In Sales" Provisions:

Generally, tie-in sales provisions are not allowed. Such a provision would require a purchaser of the warranted product to buy an item or service from a particular company to use with the warranted product in order to be eligible to receive a remedy under the warranty. The following are examples of prohibited tie-in sales provisions.

In order to keep your new Plenum Brand Vacuum Cleaner warranty in effect, you must use genuine Plenum Brand Filter Bags. Failure to have scheduled maintenance performed, at your expense, by the Great American Maintenance Company, Inc., voids this warranty.

While you cannot use a tie-in sales provision, your warranty need not cover use of replacement parts, repairs, or maintenance that is inappropriate for your product. The following is an example of a permissible provision that excludes coverage of such things.

While necessary maintenance or repairs on your AudioMundo Stereo System can be performed by any company, we recommend that you use only authorized AudioMundo dealers. Improper or incorrectly performed maintenance or repair voids this warranty.

Although tie-in sales provisions generally are not allowed, you can include such a provision in your warranty if you can demonstrate to the satisfaction of the FTC that your product will not work properly without a specified item or service. If you believe that this is the case, you should contact the warranty staff of the FTC's Bureau of Consumer Protection for information on how to apply for a waiver of the tie-in sales prohibition.

GENERAL FACTS:

What do the letters MSD stand for? Multiple Spark Discharge. It's a patented design that fires the spark plug multiple times every time the unit is triggered.

What will a MSD unit do for me? Easier starts, more horsepower, better throttle response are the expected results from a MSD capacitive discharge ignition - whether it's an analog or digital system.

Why do I need more ignition power? With the multiple spark discharge of a MSD ignition, it is finally possible to completely ignite the air/fuel mixture in the cylinder - giving you more horsepower. In a 2-stroke engine this is important. When you suddenly give the engine "the gas" after idling, the engine will bog down. This is the result of a weak stock ignition trying to burn off the excess fuel that has built up in the cylinder. The stock ignition's weak spark can't do the job. A MSD ignition has a hotter spark to start with, and along with the multiple spark discharge, a MSD ignition will thoroughly ignite the air/fuel mixture.

Spark Plug Gap With a MSD Ignition you can run a wider spark plug gap than you would be able to with a stock ignition. The MSD Ignition has a higher voltage output and can jump the spark plug gap easier. As an example, if you normally would run a .028 inch gap on your spark plug with a stock ignition, you could run a .032-.034 inch gap with a MSD Ignition. There are variables that will affect the gap size: the higher the compression - the smaller the gap; the hotter the output of the ignition - the larger the gap, etc.

What does "Total Loss" mean? The flywheel no longer charges the battery. Usually the flywheel on a total loss system has been replaced with a light weight aluminum flywheel, without the charging magnets. Quicker acceleration is the main advantage of a total loss system since you have lightened the moving mass on the end of the crankshaft. The drawback is that you have to keep an eye on the charge level of the battery - and how often depends on how many times you use the starter (a big drain on the battery) plus how long you are out on the water. Figure about 4 to 6 hours of ride time starting off with a fully charged battery that has a 17 amp-hour rating - depending on how many times you use the starter.

How do I find Top Dead Center (TDC)? TDC is where the piston has reached its highest point in the cylinder. It is the foundation to accurate timing. To find TDC, remove the spark plug and use a plunger depth gauge to judge where TDC is. If you don't have a depth gauge, place a screwdriver thru the spark plug hole until the screwdriver rests on top of the piston. Turn the flywheel until the screwdriver reaches its highest point, make a reference mark on the flywheel and a reference point on the case. Then reverse the rotation of the flywheel, allowing the screwdriver to lower down and come back up again to its highest point. Make another reference mark on the flywheel. If the two points match up - consider yourself lucky because you have an accurate crank/connecting rod/piston assembly. If the two marks don't match up, pick the point exactly between your two reference marks (using the points closest together) - this is true TDC.

Analog vs. Digital Ignitions Why the switch from analog to digital? The main advantages of a digital ignition are: accurate timing; smaller ignition box size; full access to the timing curve via dip switches; you can change the initial timing at the MSD box electronically instead of moving the trigger around physically; reliability (because there are fewer components to fail).

Can I get replacement instruction sheets? Yes. You can download instructions in the instruction section. We can also mail them, or fax them to you. All we need to know is the part number of the unit that you need replacement instructions for, and we'll be happy to get them to you.

What is RF noise? RF Noise stands for Radio Frequency noise. It is generated by spark plugs when they spark, and on motorcycles by points. RF noise causes CD ignitions to run erratically if they aren't shielded. A good way to lower RF noise is to use a good set of RF suppression spark plug wires - like MSD's 8.5 mm Super Conductor Wire or our 8mm Heli-Core wire. The Super Conductor uses a special winding procedure with a Ferro magnetic impregnated center core that is an effective RF suppression spark plug wire. In addition to using good spark plug wires, make sure that all grounds are good and clean. If you still have RF problems, shielding the ignition or moving it away from the RF source helps reduce interference.

NO SPARK:

Why don't I have spark? In most cases, it is usually due to a bad ground or no ground at all. Check all connections. Here are a few things you could check: make sure the ground wire is securely attached; that there is no paint under the ground wire; the connectors have good secure connections; there are no breaks in the wires; the battery is fully charged. Check for a bad on/off switch to the ignition box. You could have a bad coil, and switching it out for a coil that you know is good is the fastest way to determine whether a coil is the culprit. Perhaps you have a bad triggering device. Check it by removing the spark plugs (leaving the spark plug wires on), and grounding them to the engine. Next: clip the two green trigger wires coming out of the engine, and repeatedly touch the 2 wires going to the ignition box together. Make sure the power to your ignition is on. You should get a spark, or the L.E.D. (if equipped on your MSD box) should light. If you get a spark, then the trigger is bad. If the L.E.D. light turns on and there is no spark - then either you have a bad coil, a bad spark plug wire(s), or a bad spark plug(s).

REV LIMITERS:

How does a Rev Limiter work? A rev limiter does just what its name implies: it limits the revolution speed of the engine. Why is this important? If you have the throttle wide open on a watercraft and it comes out of the water, there is no load on the engine. The engine will dangerously zoom up in speed past its intended design and physical limits, possibly destroying itself. On a motorcycle if you have the throttle wide open and miss a shift, the same thing happens: a rapid increase in rpm's, possibly destroying parts. A rev limiter is placed in the electronic circuitry that prevents the engine from over-revving. At a pre-set rpm - say 7,000 rpm - the rev limiter engages. Once the engine reaches 7,000 rpm, it interrupts the signal to the coil, alternating on/off, slowing the firing sequence, and preventing the engine from rapidly shooting up in rpms. Factory rev-limiters are generally set at low rpm levels. If you have modified your engine you may not notice any performance gains due to the stock rev limiter's low rpm limit, which is why you would use a MSD Rev Limiter. With our units you can set the point, where you want the rev limiter to limit the engine's rpm.

Does a Rev Limiter automatically make my engine go faster? Only if the engine is currently being held back by the factory rev limiter. You never want to set the rev limiter's rpm cut off point too high - serious engine damage could occur.

GENERAL TUNING TIPS: You need to have all systems operating properly before you can fine tune your ignition system. Here are a few tuning tips for watercraft and motorcycles.

- Reading spark plugs is an important element of tuning. Take a good look at the insulator's ceramic coloring.

- A good light tan/gray color is perfect.

- If the plug is black with wet or dry deposits, it's usually a fouling problem. Heavy dry deposits might indicate too rich a carburetor(s), too cold a plug heat range, low compression, timing is retarded too far, or the gap is too big.

- If the deposits are wet, it could be due to a blown head gasket, bad rings or valve train problems, or too rich a carb setting.

- Silver specs, black specs, melting, or breakage at the firing tip on the plug is a sign of detonation.

- A white or real light plug color could possibly mean the carb(s) is too lean.

- Spark plug color is only accurate when checked after a high speed run, engine turned off at max rpm, and craft glided in with engine still off. No idling allowed!

- Each cylinder should be fine tuned as a separate motor/pipe/carb combination. Not all carb screws on multiple carb set ups will necessarily be adjusted the same - or jets necessarily the same size.

There's really nothing mystical about nitrous oxide and its application for engines. Very simply, NOS made it better and safer for customer use. The following questions and answers are typical of those fielded by NOS R&D people and we hope that they will be of help to all of those who seek the winning edge. Here are answers to the most commonly asked questions about NOS Nitrous Oxide Systems, along with tech information compiled by the NOS Research and Development Team.

Will Nitrous affect engine reliability? The key is choosing the correct H.P. for a given application. A kit that uses the correct factory calibration does not usually cause increased wear. As the energy released in the cylinder increases so do the loads on the various components that must handle them. If the load increases exceed the ability of the components to handle them, added wear takes place. NOS kits are designed for use on demand and only at wide open throttle. Nitrous can be extremely advantageous in that it is only used when you want it, not all the time. All NOS kits are designed for maximum power with reliability for a given application.

Can I simply bolt a nitrous kit onto my stock engine? Yes. NOS manufactures systems for virtually any stock engine application. The key is to choose the correct kit for a given application; i.e., 4 cyl. engines normally allow an extra 40- 60 HP, 6 cyl. engines usually work great between 75-100 extra HP, small block V8’s (302/350/400cid) can typically accept up to 140 extra HP, and big block V8’s (427-454) might accept from 125-200 extra HP. These suggested ranges provide maximum reliability from most stock engines using cast pistons and cast crank with few or no engine modifications.

What are some of the general rules for even higher HP gains? Generally, forged aluminum pistons are one of best modifications you can make. Retard ignition timing by 4-8 degrees (1 to 1-1/2 degrees timing retard per 50 HP gain). In many cases a higher flowing fuel pump may be necessary. Higher octane (100+) racing type fuel may be required as well as spark plugs 1 to 2 heat ranges colder than normal with gaps closed to .025"-.030". For gains over 250 HP, other important modifications could be necessary in addition to those mentioned above. These special modifications may include a forged crankshaft, a high quality race type connecting rods, a high output fuel pump dedicated to feeding the additional fuel demands of the nitrous system, and a racing fuel with high specific gravity and an octane rating of 110 or more. For more specific information about your application, please contact the NOS technical dept.

How does nitrous work? Nitrous oxide is made up of 2 parts nitrogen and 1 part oxygen (36% oxygen by weight). During the combustion process in an engine, at about 572 degrees F, nitrous breaks down and releases oxygen. This extra oxygen creates additional power by allowing more fuel to be burned. Nitrogen acts to buffer, or dampen the increased cylinder pressures helping to control the combustion process. Nitrous also has a tremendous “intercooling” effect by reducing intake charge temperatures by 60 to 75 degrees F.

How much performance improvement can I expect with a nitrous system? For many applications an improvement from 1 to 3 full seconds and 10 to 15 MPH in the quarter mile can be expected. Factors such as engine size, tires, jetting, gearing, etc. will affect the final results.

How long can I hold the nitrous button down? It is possible to hold the button down until the bottle is empty. However 15 continuous seconds at a time, or less, is recommended.

When is the best time to use nitrous? At wide open throttle only (unless a progressive controller is used). Due to the tremendous amount of increased torque, you will generally find best results, traction permitting, at early activation. Nitrous can be safely applied above 2,500 RPM under full throttle conditions.

What kind of testing or research is performed on NOS products? NOS maintains a complete research and development center including computerized dynamometer equipment as well as a nitrous/fuel flow testing facility. In addition, NOS is actively involved in many aspects of racing: working closely with many top name racers to develop the most powerful and reliable nitrous systems in the world.

How long will the bottle last? This largely depends on the type of nitrous kit and jetting used. For example, a 125 HP Power Shot kit with a standard 10 lb. capacity bottle will usually offer up to 7 to 10 full quarter-mile passes. For power levels of 250 HP, 3 to 5 full quarter-mile passes may be expected. If nitrous is only used in 2nd and 3rd gears, the number of runs will be more.

Will I have to re-jet my carburetor on my car when adding nitrous? No! The NOS system is independent of your carburetor and injects its own mixture of fuel and nitrous.

Is nitrous oxide flammable? Nitrous Oxide by itself is non-flammable. However, the oxygen present in nitrous oxide causes combustion of fuel to take place more rapidly.

Will nitrous oxide cause detonation? Not directly. Detonation is the result of too little fuel present during combustion (lean) or too low of an octane of fuel. Too much ignition advance also causes detonation. In general, most of our kits engineered for stock type engines will work well with premium type fuels and minimal decreases of ignition timing. In racing application where higher compression ratios are used, resulting in higher cylinder pressures, a higher fuel octane must be used as well as more ignition retard.

Where can I get my bottle refilled? Simply call 1-800-99-REFILL for the location of the nearest NOS dealer with refilling capabilities.

Is there any performance increase in using medical grade nitrous oxide? None! NOS recommends and sells only the automotive grade, called Ny-trous Plus. Ny-trous Plus contains a minimal amount of sulfur dioxide (100 ppm) as a deterrent to substance abuse. The additive does not affect performance.

Is it a good idea to use an aftermarket computer chip in conjunction with an NOS System? Only if the chip has been designed specifically for use with nitrous oxide. Most aftermarket chips use more aggressive timing advance curves to create more power. This can lead to possible detonation. You may wish to check with the manufacturer of the chip before using it. The top manufacturers, such as Hypertech do make special chips for use with nitrous.

How long does it generally take to install an NOS kit? The majority of NOS kits can be installed using common hand tools in approximately 4 to 6 hours. NOS instruction manuals are by far the best in the industry and include specific installation drawings, wiring diagrams, and bottle mounting procedures as well as performance tips and a thorough trouble shooting guide.

Which type of manifold is better suited for a plate injector type of nitrous system, single or dual plane manifold? As long as the manifold doesn’t interfere with the spray pattern of the bars, either will work fine in most cases. The distribution is better with a single plane at high RPM. If your goal is to increase power by more than 150 HP, the single plane manifold is better.

Does nitrous oxide raise cylinder pressure and temperatures? Yes. Due to the ability to burn more fuel, this is exactly why nitrous makes so much power.

Are there any benefits to chilling the nitrous bottle? No. Chilling the bottle lowers the pressure dramatically and will also lower the flow rate of the nitrous causing a fuel rich condition and reducing power. On cold evenings you might run on the rich side. For optimal running conditions, keep bottle pressure at approximately 900-950 psi. NOS has a nitrous pressure guage that allows you to monitor this. If you live or operate a nitrous system in colder temperatures, it may also be a good idea to purchase a bottle heater kit, part #14164. Generally, ambient temperatures of 80-90 degrees Fahrenheit will allow for best power potential of NOS kits.

Are there benefits to using nitrous with turbo or super-charger applications? Absolutely! In turbo applications, turbo lag is completely eliminated with the addition of a nitrous system. In addition, both turbo and superchargers compress the incoming air, thus heating it. With the injection of nitrous, a tremendous intercooling effect reduces intake charge temperatures by 75 degrees or more. Boost is usually increased as well, adding to even more power.

How complete is an NOS kit? NOS prides itself on offering the most complete systems on the market today. They include virtually every component that may be needed for a complete installation; parts such as extra long carburetor studs, gaskets, pipe tap, fuel hose, brackets, filters, fittings, hardware, wiring, 10 lb. bottle with Hi-Flo valve, comprehensive instruction manual, and all other major components are standard in every NOS kit.

What is the difference between a standard and an NOS Hi-Flo bottle valve? The orifice of the Hi-Flo valve is much larger than the standard valve allowing for a larger flow of nitrous. With a small orifice valve a pressure drop could occur when nitrous flow is high; causing surging or inadequate nitrous flow. The NOS Hi-Flo valve eliminates this problem. NOS Hi-Flo valves are standard in all NOS kits.

What affect does nitrous have on an engine with considerable miles on it? This depends largely on the actual condition of the engine components. Any performance modification to an engine that is worn out or poorly tuned will have detrimental effects. However, an engine in good condition, with good ring and head gasket sealing, should be able to use nitrous without any abnormal wear.

Will the use of nitrous oxide affect the catalytic converter? No. The increase in oxygen present in the exhaust may actually increase the efficiency of the converter. Since the use of nitrous is normally limited to 10-20 seconds of continuous use, there usually are no appreciable effects. Temperatures are typically well within acceptable standards.

How important is it to use nitrous and fuel filters in a kit? Some of the most important components of any nitrous system are nitrous and fuel filters. To keep contaminants from attacking the solenoid or plugging up a jet, NOS nitrous filters feature a special stainless steel mesh element from the aerospace industry.

Will the percentage of performance increase be the same in a highly modified engine compared to a stock engine when using the same NOS kit and jetting? Not really. In most cases the percentage of increase is greater from a stock engine because it is not as efficient as the modified engine in a normal non-nitrous mode. However, since the effects of nitrous oxide magnify the output of any engine, the total power output will be much higher in the modified engine.

Can high compression engines utilize nitrous oxide? Absolutely. High or low compression ratios can work quite suitably with nitrous oxide provided the proper balance of nitrous and fuel enrichment is maintained. NOS kits are used in applications from relatively low compression stock type motors to Pro-Modifieds, which often exceed 15 to 1. Generally, the higher the compression ratio, the more ignition retard, as well as higher octane fuel, is required. For more specific information talk to one of our technicians.

Can service station fuel be used for street/strip nitrous oxide applications? Yes. Use of a premium type leaded or unleaded fuel of 92, or greater, octane is recommended for most applications. Many NOS systems are designed for use with service station pump gas. However, when higher compression or higher horsepower levels are used, a racing fuel of 100 octane, or more, must be used.

What type of cam is best suited for use with nitrous oxide? Generally, cams that have less exhaust overlap and more exhaust duration. However, it is best to choose a cam tailored to normal use (when nitrous is not activated) since 99% of most vehicle operations is not at full throttle. There are special cam grinds available for nitrous competition which have more aggressive exhaust profile ramping, etc. Since cam selection depends largely on vehicle weight, gearing, etc., it is best to stick to cam manufacturers’ recommendations for your particular goal.

What type of nitrous system is better; a plate injection system or a direct port injection system? The advantages of a plate system are ease of installation and removal, ability to transfer easily to another vehicle, ability to change jetting combinations quickly, and in most cases, provide you with all the extra HP you will ever need (75 to 350 more HP). In some cases, such as in-line type engines with long runners, a direct port type system is advisable for maximizing distribution. Also, where more than 350 HP is needed, our direct port Fogger systems will provide the ultimate in distribution and power (up to 500+ HP). Direct port injection is also desirable when the system is hidden under the manifold.

Should I modify my fuel system to use nitrous oxide? Most stock fuel pumps will work adequately for smaller nitrous applications. It is important to check to see if your pump can flow enough fuel to your existing fuel system (whether carburetor or fuel injected), as well as being able to supply the additional fuel required by the nitrous kit under full throttle conditions. It may be a good idea to dedicate a separate fuel pump to the nitrous kit.

Which is the best position to mount a nitrous bottle? NOS bottles come with siphon tubes and, in order to maintain proper nitrous pickup, it is important to mount the bottle correctly. We recommend mounting the bottle at a 15 degree angle with the valve end higher than the bottom of the bottle. The valve end of the bottle should point to the front of the vehicle and the valve knob and label should face straight up.

What are the advantages of using nitrous compared to other performance options? The cost of many other performance options can put you in the poorhouse. Dollar for dollar, you can’t buy more performance with less money than nitrous. With a nitrous system, performance and reliability can be had for a much more reasonable price while still retaining the advantage of a stock engine during normal driving. Nitrous offers tremendous gains in torque without having to rev the engine to excessive rpm’s. These factors help your engine last longer than many other methods of boosting horsepower.

Does NOS manufacture kits for motorcycles, water craft, or snowmobiles? Absolutely. Call or write NOS to obtain our special catalog devoted specifically to these applications.

What kind of pressures are components subject to in a typical nitrous kit? Pressures often exceed 1,000 psi. This is why NOS uses only high pressure tested aircraft quality components like stainless steel braided Teflon lines throughout its system.

What is the function of the blow-off safety valve on the bottle? It is very important not to overfill a bottle; i.e., a 10 lb. capacity bottle should not be filled with more than 10 lbs. of nitrous oxide by weight. Over-filling and/or too much heat can cause excessive bottle pressures forcing the safety seal to blow and releasing all the contents out of the bottle.

Will I have to change my ignition system? Most late model ignition systems are well suited for nitrous applications. In some higher HP cases, it may be advisable to look into a high quality high output ignition system with a built in spark retard.

How do I know how much nitrous is left in the bottle? The most reliable method is to weigh the bottle to determine how many pounds remain. When a bottle is near empty (about 20% or less nitrous remaining) a surging effect is normally felt.

DYNATEK SPORTBIKE IGNITION

If my particular model is not listed in the applications section, can I adapt on to my model? All Dynatek ignitions are developed to be model specific. We do not advocate or recommend fitment to any models for which it was not designed. However, we are familiar with some adaptations, please call or email. Feel free to email your specific model information (year, make, model, and engine size) to Info@dynaonline.com along with the type of product you are seeking. We maintain files on applications we do not currently have available and review them periodically for consideration in incorporating them into our line up.

What type of spark plug wires should I use? The Dyna 2000 Series ignition requires a good quality suppression core / resistor wire for optimum performance. Use of a copper core wire may result in poor or erratic performance, unless used with the stock resistor plug cap.

What coils should I use? The stock coils usually will work fine. To optimize the spark output to its full potential, use Dynatek performance coils. Please call our Technical Support Department at 800 928-3962 or email us atInfo@dynaonline.com for the correct coil kit part number.

What spark plugs should I use? In most cases, the stock spark plug and cap will work great. For heavily modified motors, consult with your engine builder for their recommendations, as incorrect spark plug may result in severe engine damage or loss of performance.

Why does my Dyna S spark continuously when I am charging the battery? Battery chargers constantly switch between high and low voltage. The Dyna S see’s this as the ignition being switched on and off resulting in the constant spark described above.

DYNA 2000- HD

Will my stock pickup work in single fire mode with the Dyna 2000? How? Yes, the stock Harley-Davidson pickup will work perfectly with the Dyna 2000 in single fire applications. Because of the uneven firing angle of the Harley engine, the microprocessor in the Dyna 2000 is able to separate the firing pulses below idle, resulting in a true single fire ignition.

What type of spark plug wires should I use with the Dyna 2000 ignition? Any type of carbon suppression core spark plug wires should be compatible with the Dyna 2000. Do not use solid core or spiral core type plug wires. The factory Harley wires should work fine. Dynatek does not recommend the use of Nology wires with our microprocessor controlled ignition systems.

Should I use the VOES on my late model Harley with the Dyna 2000? Most stock or mildly modified Harleys will benefit from the use of the VOES. The way the system works is; at part throttle or cruising speeds, when engine vacuum is high, the switch is closed and the ignition is at full advance by 1500 rpm. This results in increased fuel economy and improved part throttle drivability. When under heavy acceleration, and engine vacuum is low, the switch opens, causing the Dyna 2000 to follow a slower advance curve. This helps to reduce detonation under heavy loads. More heavily modified motors can benefit from using the VOES switch wires in the optional modes outlined in the instruction manual.

What is the difference between Single Fire and Dual Fire? What are the benefits? Dual fire ignition systems fire both spark plugs from a single coil at the same time. The majority of the spark energy goes to the cylinder under compression while a small portion goes to the cylinder on the exhaust stroke causing a small wasted spark. Single fire ignitions separate the firing pulses, only firing the cylinder under compression. The main advantage of dual fire systems is simplicity and low cost. The advantage of single fire systems are smoother engine operation and the elimination of the popping that sometimes occurs when long duration camshafts are used. There is no horsepower advantage with single fire ignition systems.

How do I hook up my tach to the Dyna 2000? . In dual fire installations, you may use the factory tach connection or you can use the tach output provided with the Dyna 2000-HD1E. For single fire applications, you must use the Dyna 2000 tach output green wire for correct single fire operation.

What coil should I use with the Dyna 2000? For all dual fire and single fire applications, you must use coils that have a primary resistance of 2.5 to 3.5 ohms.

DYNA2000I

Can I kick start my motor with the 2000i installed?How? Yes, but it will require reprogramming the dead revs back to zero (0). Out of the box, the 2000I has 3 dead revs like a stock Harley-Davidson System. This is also a benefit for high compression motors using an electric starter. The kick must not start on the compression stroke (sensor in the window on the cup). Stopping ‘in the window’ will execute the soft turn off. The leading AND trailing edges of the window must be seen by the 2000i to make a spark.

Can I run a tach? Yes the green wire in the 2000i loom is a dedicated one (1) pulse per revolution tach output signal.

My motor stalled and the red LED was flashing continuously. What is wrong? The ignition has sensed either too much current or a short circuit draw from the coil (S), or seen excessive charging system voltage. This should be examined prior to condemning the 2000i. Also, be sure to check the chassis ground and the ground cable (s). A poor ground can also cause a random stall.

Should I use the VOES on my late model Harley with the Dyna 2000i? Most stock or mildly modified Harleys will benefit from the use of the VOES. The way the system works is; at part throttle or cruising speeds, when engine vacuum is high, the switch is closed and the ignition is at full advance by 1500 RPM. This results in increased fuel economy and improved part throttle drivability. When under heavy acceleration and engine vacuum is low, the switch opens, causing the Dyna 2000i to follow a slower advance curve. This helps to reduce detonation under heavy loads. More heavily modified motors can benefit from using the VOES switch wire in the optional modes outlined in the instructions manual.

What type of coils do I need to use? Most coils with 2.5-3.5 ohms resistance can be used. For coil application, see the installation guide. If you are unable to determine the coil(s) you need, please call or email us at the number above

Will the 2000i work on my Panhead? No. The 2000i uses the 2nd sensor to convert 315/405 degrees to 360 degrees. Reverse rotation prevents proper 2nd sensor operation – no window is ever seen. (The 2nd sensor only looks for the window when the primary sensor sees the leading edge of its window.)

TC88

Will the TC88-3 and DSPT-1 (Sportster) module interchange? No. The units each have model specific timing curves and rev limits should never be interchanged.

How come my motor seems to be harder to start or sometimes kick back? The TC88 ignition, being a high performance oriented ignition, has a great need for proper voltage than the stock module. It is important that the battery be in good condition, full charged, and the cables be in good condition and the ground proper, clean and secure. Unlike EVO engines that use a Hall sensor that functions properly at zero RPM, Twincam engines use a Variable Reluctance crank sensor, which produces zero signal at zero RPM. The Dyna ignitions require a minimum of 60 RPM at each of the 30 pulses the crank sensor sees each engine revolution

I want to build a custom Twincam and need to wire the ignition. How do I do it? Use the TC88-2P module. For the best results, use a wiring harness from a specialty after market manufacturer, such as Wires Plus, made specifically for the this type of application. If you elect to try making your own harness, the pin outs are the same on the unit as the stock model. At a minimum for the ignition, you will need to install a map sensor, crank position sensor and correct Twincam .5 ohm coil, or our Dyna DC6-6 coil.

What type of spark plug wire do I need? You need a good quality resistor/ suppression core wire. The stock Harley Twin Cam wires work well. Dynatek also carries quality wire kits. Dynatek does not recommend the use of Nology wires with our microprocessor controlled ignition systems.

DYNA S

Will the Dyna –S work in my Evolution style case? Yes. However you will need to install an early style mechanical advancer from any Harley-Davidson shop or store.

Where do the black and white wires go on the DS6-2? The white wire connects to the negative (-) side of the rear cylinder coil, the black wire connects to the negative side of the front cylinder coil.

Will the Dyna S work in early Panhead applications with reverse rotation distributors? Yes the Dyna S works in these applications extremely well. Just remember that in these reverse rotation applications that the front cylinder becomes the rear for ignition purposes. When using the DS6-2 single fire, simply reverse the black and white wires. With the DS6-1 dual fire, simply use the rear cylinder timing marks. Some modification to the mounting plate may be necessary for proper clearance.

Where do the blue and white wires connect on the DS6-1 dual fire Dyna S The white wire connects to the +12 volt side of the coil, the blue wire connects to the negative (-) side of the coil.

Why does Dynatek recommend 5 ohm coils for street use and 3 ohm coils for racing? The resistance of the coil determines how much current flows through the ignition system. The 3 ohm coils, because of their lower resistance, pass more current and therefore run warmer than the 5 ohm coils. If the coils are located where they receive good airflow and are away from engine or exhaust heat, then 3 ohm coils will generally give reliable service on the street. However, when the coils are located under the tank, between the cylinders, or close to the engine with a tight fitting cover, 3 ohm coils may overheat. This is most likely to occur under worst case conditions, such as creeping along in traffic on a hot day in Arizona (this isn¹t so great for an air cooled engine either!). Rather than get into the specifics of every application we make the general recommendation - 5 ohm for street, 3 ohm for race. NOTE: DO NOT use the DC6-5 coil with the DS6-2. Damage to the coil and ignition will result and will NOT be warranted.

What should I set my spark plug gaps to? The gap settings listed below can be used as a starting point to obtain satisfactory performance with our ignition system. Any benefit from running larger or smaller gaps will need to be determined by experimenting with your particular engine combination.

- Single Fire - Single Plug: .035 to .040

- Single Fire - Dual Plug: .022 to .025

- Dual Fire - Single Plug: .035 to .040

- Dual Fire - Dual Plug: .035 to .040 - When wired so each coil fires a plug in each cylinder.

Why does my Dyna S spark continuously when I am charging the battery? Battery chargers constantly switch between high and low voltage. The Dyna S sees this as the ignition being switched on and off resulting in the constant spark described above.

Power Commander General Questions

Applicable to PC III USB:

I see your PCIIIusb software works with Windows 98 “SE”. What does the “SE” mean?

The “SE” means Second Edition. The first version of Windows 98 did not properly support USB devices. If you go into “Control Panel” in Windows and double click the “System” icon the version number is displayed. If the version number is 4.10.2222, it is the “SE” version.When I connect my PCIIIusb to my computer running Windows 98SE, it asks for “drivers”. Where do I get these?

The drivers required are found on the install disk for Windows 98SE. We have also put copies of the necessary drivers in a folder named Win98 on the Power Commander CD.I am trying to communicate with my PCIIIusb using the supplied 9 volt adapter, but the computer does not see it. What should I check?

A low battery will keep the PCIIIusb from communicating. The PCIIIusb can quickly drain (about 20 minutes of use) a new battery, so make sure to not leave it plugged in longer than necessary. Also, make sure the cable is pushed all the way into the PCIIIusb’s port. Sometimes the connector needs a fair amount of pressure to fully seat it.The Power Commander software says "Serial: N/A" at the top right hand corner of the screen and does not show any serial numbers or "TP" readings.

The Power Commander USB needs to be powered up by either the bike or a brand new 9 volt battery via the battery adapter. If the unit is not powered up, the computer will only see a USB device being plugged in, but will not allow the software to communicate. If a battery has been plugged in for around 5 minutes, it may be too low on power to allow good communication.The message "Power Commander not found" comes up on my interface. What does that mean?

The software is not communicating with the Power commander,. Make sure that the ignition switch is on, the kill switch is in position, and the USB cable is firmly connected to both the Power commander and the computer. Make sure that the unit is staying powered up (green light will be lit on the face of the unit) and the your cable is connected. The USB cable needs to "snap" into place. Applying ample pressure is sometimes required.When I adjust my Power Commander using the faceplate buttons and then do a "get all" with the software I do not see any changes to the map. Is this normal?

When adjusting the buttons, these changes will not be shown in the cells of the software.The firmware program does not appear to work and I get an error code that has a "0x005, 0x008, 8001" or something similar.

These errors appear to be communication related. Unplug the USB cable from the programmer and switch USB ports on the computer. If the error still comes up, try switching the USB port to another one and restart the computer while the programmer is plugged into the USB cable. This should refresh the USB port. Power to the programmer does not need to be attached.The Power Commander 3 USB does not power up anymore after loading the firmware for my ignition module.

The firmware did not load correctly and needs to be reloaded.The Start-up Fuel and Rev Xtend features are not showing up in the Power Commander III USB software's features dialog box.

When installing the firmware, the "Update Settings" function of the firmware loading process did not go through correctly.How can I tell what PCIII USB Control Center Software version I have?

Open the PCIII USB Control Center application on your computer, and go to the "Help" menu at the top. From the "Help" menu click on "About Power Commander 3 USB Software" to find your version.I'm having trouble installing the Accelerator Pump Utility to my PC3USB

Verify that the latest version of the PCIII USB Control Center Software is installed on your computer and can communicate with the power commander- Close all Power Commander Applications on your computer.

- Install the Accelerator Pump Utility to your Desktop and open it.

- Verify that "Accelerator Pump Feature Enabled" is displayed by clicking on the Enable Accelerator Pump Feature Button.

- Close the Accelerator Pump Utility that is open on your desktop.

- Open the PCIII USB Control Center Software that is on your computer.

- Go to the "Power Commander Tools" menu and then to "Accelerator Pump Configuration" to make the required setting changes for your style of riding, then click OK .

Applicable to All Models

I bought a bike that had a Power Commander on it. Can I buy the software and cable I need to program it from you?

All of the software, map files, etc., can be obtained from Power Commander's download page. The USB cable is a USB to Mini-B cable and it can be purchased at any computer store. If you would still like to purchase a CD you can do so.File and Power Commander version incompatible error appears when I try to load a map

This message will appear if you try to load a map from a different make or model than the Power Commander is connected to. (i.e. attempting to load a Harley map to a Suzuki).What ranges (low, mid, high) do the face plate buttons affect my fuel curve?